- Choose a Capability

- Aqueous Cleaning

- CNC Bending

- CNC Coiling

- CMM & 5 Axes Laser Measuring

- Engineering & Tool Design

- Fittings Installed /

End Preparations Performed - Facilities

- Inventory & Logistics

- Kitting

- Lean Manufacturing

- Machining

- Magnetic Forming

- Non Destructive Testing

- Precision Cleaning Facility

- Precision Laser Cutting

- Proof Pressure Testing

& Auto Frettage - Part Marking, I.D. & Label

- Quality & Inspection

- Rapid Proto-Typing

& Fixture Cell - Sheet Metal Fabrication

- Welding

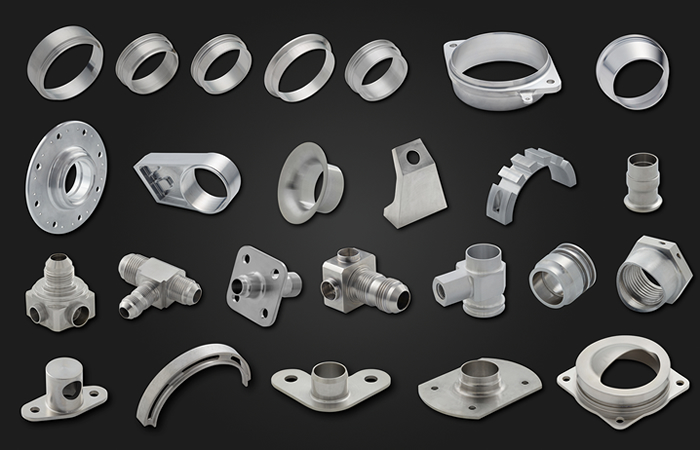

Machining

STEICO has designed and built a complete machining facility dedicated to its detail machined parts and tooling needs. This facility utilizes the latest CNC machining and inspection processes allowing extremely high quality, tight tolerance machining in a closed loop rapid process including on site Kan Ban raw materials and logistics support.

Equipment includes but is not limited to:

Mori Seiki: Model NLX2500SY-700

- 4 Axis Turn-Mill

- Capacity 10.0” Dia X 25”

- Bar Capacity 3”

- Sub-Spindle

- Full Y Axis 4” Travel

- Hi Pressure Coolant System

Mori Seiki: Model DuraVertical 5100

- 3 Axis Vertical Mill Equipped with Integrated 5th Axis Trunnion

- 30 Tool Magazine 23" x 53" Table

- 12,000 RPM Spindle – High Pressure Coolant-Through Capability

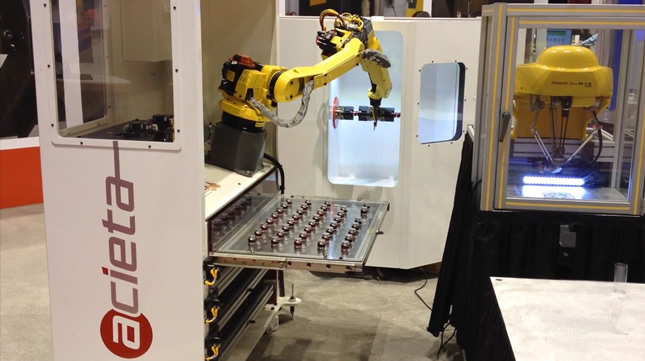

Machine Tool Robotic Workcell

MANUFACTURER: ACIETA

FEATURES:

- Fanuc 6 axis M20iA robot, ± .003" positional repeatability

- 4 drawer part loading/unloading capacity

- Dual back to back three jaw gripper system

- 44 lb part capacity

- Safety protection using laser scanner to eliminate need for fencing around workcell