- Choose a Capability

- Aqueous Cleaning

- CNC Bending

- CNC Coiling

- CMM & 5 Axes Laser Measuring

- Engineering & Tool Design

- Fittings Installed /

End Preparations Performed - Facilities

- Inventory & Logistics

- Kitting

- Lean Manufacturing

- Machining

- Magnetic Forming

- Non Destructive Testing

- Precision Cleaning Facility

- Precision Laser Cutting

- Proof Pressure Testing

& Auto Frettage - Part Marking, I.D. & Label

- Quality & Inspection

- Rapid Proto-Typing

& Fixture Cell - Sheet Metal Fabrication

- Welding

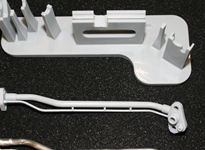

Rapid Proto-Typing & Fixture Cell

STEICO Industries is leading the industry with advanced fixture manufacturing methods.

- Fixture Lead Time = 24hrs vs. Weeks

- Close to Perfect Quality and Tolerances

- Inexpensive

- Rapid to Produce, Therefore Reducing Customer’s Initial Lead Times

Assembly fixtures utilize aluminum and steel base plates manufactured as a solid foundation, drilled and tapped in one process utilizing our 3 axes.

- WardJet Water Jet - Model: Z-2043

- Cutting envelope: 79" x 157.5" (6.5 ft x 13 ft)

- One cutting head - One tapping head

- Positional Accuracy of ±.003”, Repeatability of ±.001